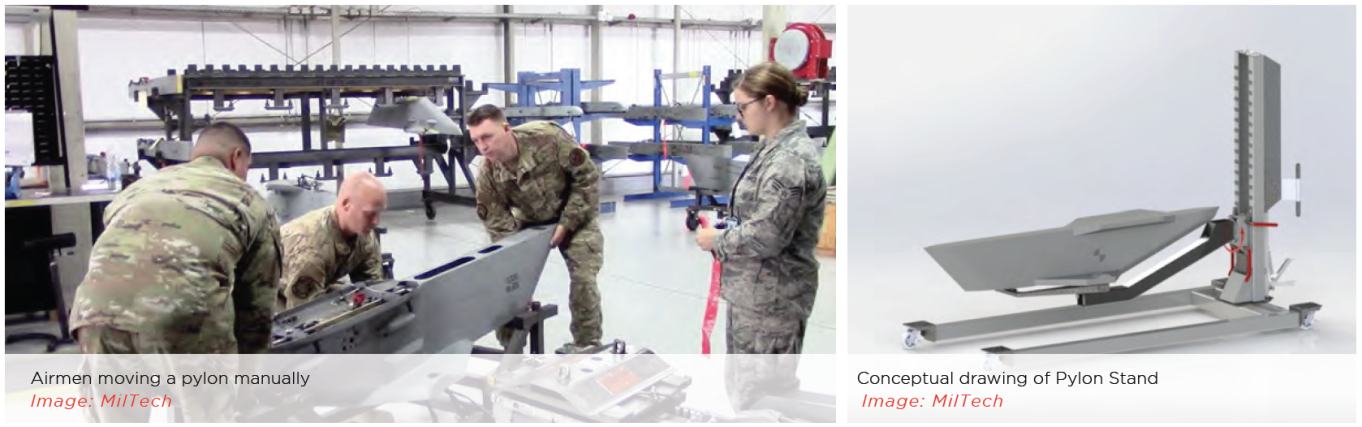

Listening to and implementing end-user feedback resulted in a maintenance technology that reduced development time, cost, damage to pylons and injuries to personnel.

PROTECTING AIRMEN AND AIRPLANES

Benefit

Engagement Process

Airmen from Spangdahlem AFB approached their leadership about a concept for improved handling of F16 pylon stands. The current process has a high injury rate and takes excessive time to complete. Spangdahlem leadership contacted MilTech to assist with listening to end users, formalizing the pylon modification, and identifying potential vendors for parts so that it could be easily manufactured and serviced. MilTech identified and partnered with industry SMEs to mature the stand design. Based on feedback from personnel at the 52nd Fighter Wing, industry partners then created a physical manifestation of the inventor’s design for testing and evaluation.

Results

Within a year from contacting MilTech, the 52nd Fighter Wing will have an updated pylon stand for evaluation. MilTech’s access to nontraditional industry partners allowed the development of evaluation samples much faster than the Air Force anticipated. When the pylon stand is fielded, airmen will have a tool that makes their work faster, easier, and safer.

Estimated ROI Impacts

- Reduced Airman injuries

- Reduced repair and evaluation time

- Delivered for 25% of the estimated time and cost

The views, conclusions, and metrics contained herein are those of the authors and should not be interpreted as necessarily representing the official policies or endorsements, either expressed or implied, of the United States Government.