Technology scouting and vendor assistance helps AFLCMC maintain legacy equipment to enhance readiness and air superiority.

Nontraditional Vendors Support Air Superiority

Benefit

Engagement Process

DOD’s sustainment centers must maintain legacy equipment with components that are often no longer available. AFLCMC requested MilTech’s assistance to help solve parts shortages for the TF-33 engine (Tinker AFB’s Propulsion Division) and the TPS-75 Radar System (Hill AFB). MilTech engaged with industry, academia, and consortia to identify and qualify non-traditional vendors to address modernization, redesign, manufacturing, and supply chain challenges involved with the legacy parts.

These industry partners can manufacture replacement items cost-effectively, enabling the Air Force to improve reliability and readiness.

Results

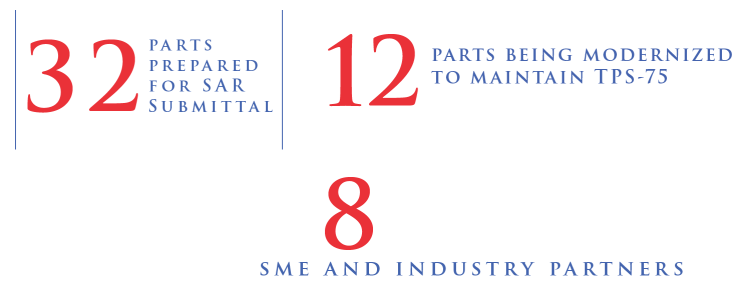

MilTech’s access to manufacturing SMEs and nontraditional industry partners has resulted in multiple components becoming available for procurement. Many components are modernized, while still maintaining current fit and function (when approved by AFLCMC), increasing reliability and longevity. Successful engagement of industry partners has led to ongoing work and a broader industrial base.

Estimated ROI Impacts

- Formerly unavailable parts now in stock, improved readiness for TPS-75 systems

- Reduced maintenance and procurement costs

- Improved capability

The views, conclusions, and metrics contained herein are those of the authors and should not be interpreted as necessarily representing the official policies or endorsements, either expressed or implied, of the United States Government.